When diving into the world of 3D printers, it’s important to understand the various technologies that make them work.

Each type has its own unique method of turning digital designs into real-life objects, and knowing the basics can help you choose the right one for your needs.

First up is Fused Deposition Modeling (FDM). This is the most common type you'll find on the market. It works by melting plastic filament and laying it down layer by layer to build your object. It’s user-friendly and perfect for beginners. Plus, you have a wide variety of filament materials to choose from, making it great for different projects!

Next, there's Stereolithography (SLA). This technology uses a laser to cure liquid resin into solid pieces. SLA printers can produce highly detailed and smooth finishes, making them ideal for intricate designs. However, they usually come with a higher price tag and may require a bit more maintenance and safety precautions due to the resin.

Selective Laser Sintering (SLS) is another impressive method. It uses a laser to fuse powdered material, typically nylon or other plastics, into solid parts. This allows for complex designs without the need for support structures, but SLS printers tend to be on the pricier side and are usually found in industrial settings or advanced hobbyist circles.

Finally, let’s not forget Digital Light Processing (DLP), similar to SLA but often faster. DLP uses a digital light projector to cure resin in layers, offering an excellent balance between speed and detail. It’s perfect for anyone needing quick prototypes without sacrificing quality.

Choosing the Right 3D Printer for You

So, you're ready to dive into the world of 3D printing? That's awesome! But with so many options out there, how do you pick the right 3D printer for your needs? Here are some key factors to consider to help you make the best choice.

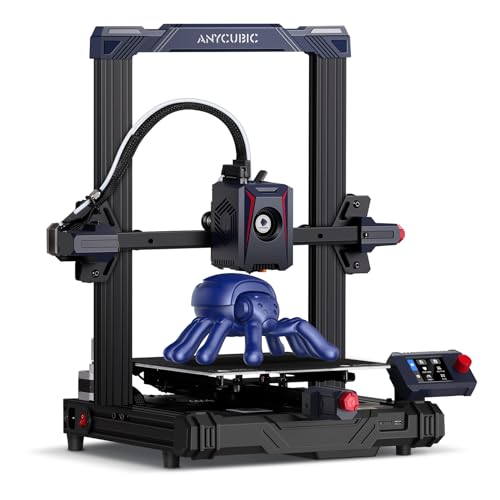

First off, think about what you want to print. If you’re planning on creating detailed miniatures or intricate designs, a resin printer might be your best bet. They produce high-quality prints but can be a bit messier to deal with. On the other hand, if you’re looking to print larger objects, a filament printer (like FDM) is a great option. They come in various sizes and can work with different types of plastic, providing a solid and durable finish.

Next, consider your experience level. If you're a beginner, you’ll want a user-friendly printer that’s easy to set up and operate. Look for models with simpler software and good customer support. Many brands offer beginner kits that include everything you need to get started. If you’re more experienced, you might enjoy a printer that allows for customization and tweaking.

Don’t forget to think about your budget! 3D printers can range from a few hundred to several thousand dollars. Set a budget ahead of time, and don't forget to factor in the cost of materials, like filament or resin. It’s good to shop around and read reviews to find a machine that delivers good value without sacrificing quality.

Lastly, consider the size and space you have available. Some printers can be quite bulky, so make sure you have enough room to set it up and safely store your materials. Check the printer's footprint and make sure it fits comfortably in your workspace.

Popular Types of 3D Printers Explained

When it comes to 3D printers, there are several popular types, each serving different needs and projects. Here are a few you might come across:

- FDM (Fused Deposition Modeling): This is the most common type of 3D printer. It works by melting plastic filament and layering it to create your model. It's great for beginners and offers a wide variety of materials. Plus, you can usually find replacement parts easily.

- SLA (Stereolithography): If you’re looking for high detail, SLA printers are the way to go. They use a laser to cure liquid resin into solid form. The results are stunning, making it ideal for detailed miniatures or jewelry. However, the resin can be more expensive and a bit messier to work with.

- SLS (Selective Laser Sintering): For more robust prints, SLS printers use a laser to fuse small particles of plastic, metal, or ceramics. This method is popular in industries that need strong, functional parts, like aerospace or automotive. It does tend to cost more, but the results are professional-grade.

- DLP (Digital Light Processing): Similar to SLA but typically faster, DLP uses a digital light projector to cure resin layer by layer. This means you can quickly produce high-resolution items. It’s perfect if you need a quick turnaround without sacrificing quality.

No matter which type you choose, there’s a 3D printer out there that can meet your specific needs. Just think about the projects you want to tackle, and you’ll find the perfect fit!

Tips for Getting Started with 3D Printing

Getting started with 3D printing can feel a bit overwhelming, but it’s a fun adventure once you dive in! Here are some tips to help you get rolling.

First, choose the right printer for your needs. If you're a beginner, consider starting with an entry-level printer. Look for ones that come mostly assembled and have a good community support base. Brands with user-friendly software make a big difference, too!

Next, familiarize yourself with 3D printing software. There are tons of free and paid options out there. Tinkercad is a great place to start if you're new to design because it's intuitive and web-based. Just play around and have fun with it!

Don't forget about the materials! PLA is a great choice for beginners because it’s easy to print with and works well for most projects. As you get more experienced, you can explore other materials like ABS or PETG for different results.

Finally, patience is key. Your first few prints may not turn out perfectly, but that’s part of the learning process! Take notes about what works and what doesn’t, and soon you’ll see your skills improve.